Why Use Suction-Blast Rotary Heads?

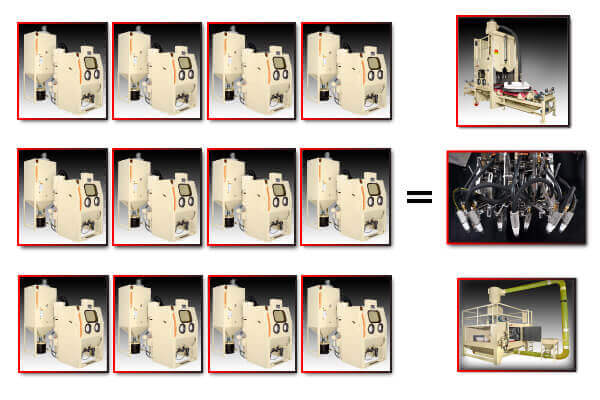

Empire’s Rotary Head Blast Systems are automated media and recovery systems used in the process of media blasting. Our Rotary Head Blast Systems service a wide range of industries, from clean energy to aerospace. The Rotary Head Blast System contributes to the outstanding performance of multiple systems that we offer such as our IL series (In-Line Conveyor), 6060 series (Rotary Batch System) and our CT series (Continuous Turntable Systems).

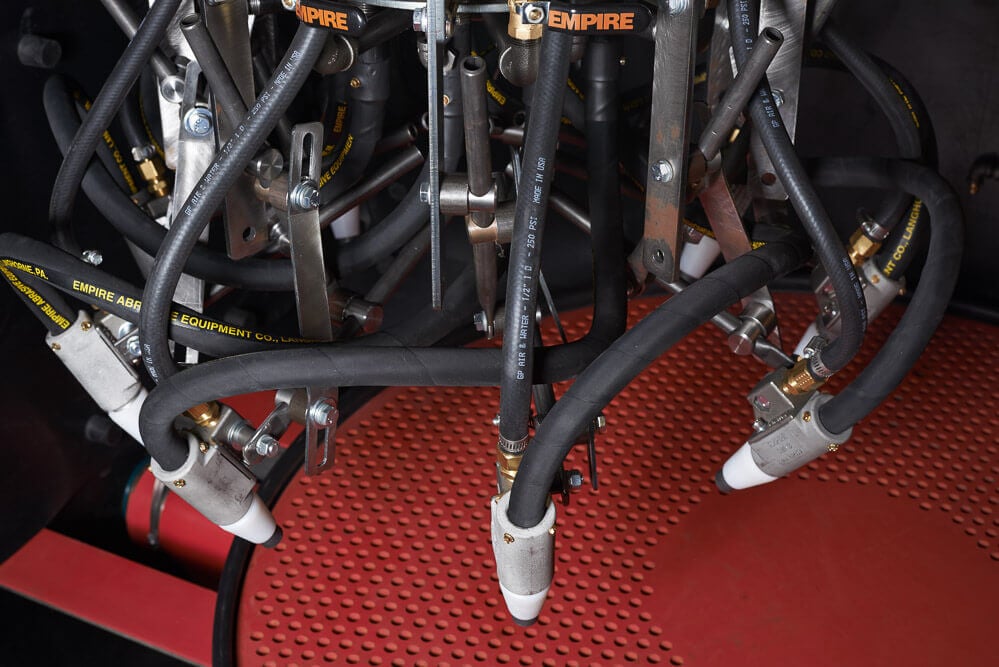

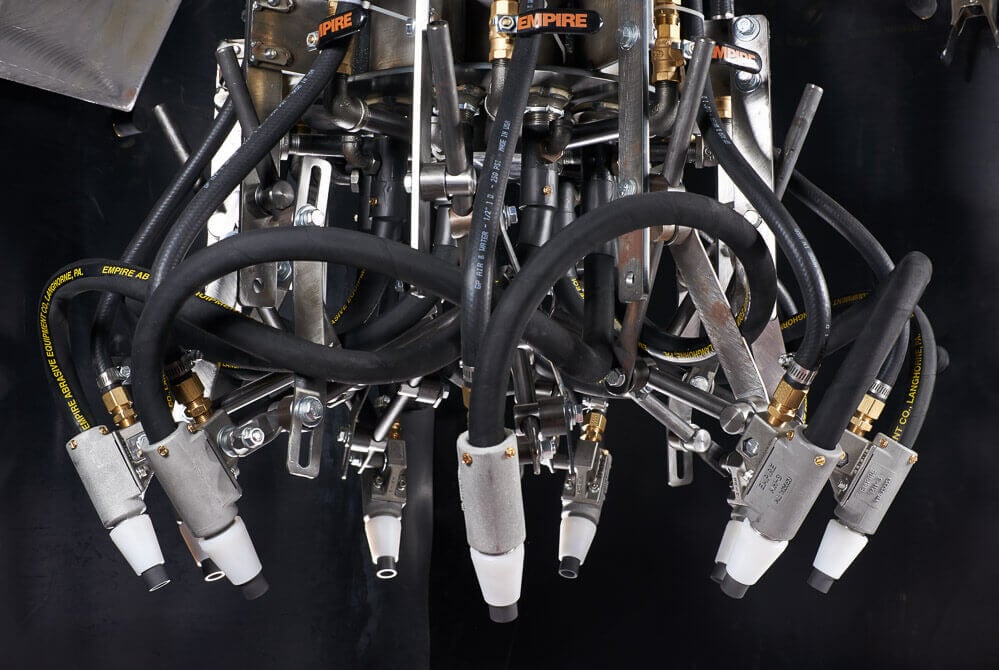

The Rotary Head System can be configured in multiple ways to meet your applications. It can be configured with four, six or nine Empire MH-3 Suction-Blast guns and fitted with wear resistant nozzles ranging in size from ¼ to 7/16 depending upon the needs of the application. The optimizing of the nozzle size and material greatly reduces the need for routine maintenance, therefore increasing your uptime performance.

Our MH-3 Suction-Blast guns are mounted on a variable speed rotating assembly that includes media flow regulators and universally adjustable mounting arms. Empire’s MH-3 guns are sized and set for your application. Once the arms are set in place for a given application, the arms are designed to stay locked in place and will not move during operation. If needed each Empire MH-3 gun can be turned on or off to further tune the Rotary Head to your application. This design allows for a very consistent and uniform blasting process.

Empire’s Rotary Head Blast Systems are low maintenance due to the heavy-duty design and low rpm of both the rotary head, rotary table or conveyor system. The units are designed to keep the mechanicals out of the blast media, thus providing a higher machine uptime. This efficient design also allows for easier maintenance if it is ever needed.

Another key design feature of Empire’s Rotary Head Blast Systems is the simplicity of part setup that typically requires no part fixturing or tooling – simply place the part on the powered turntable or conveyor belt, press the start button and blast. Depending upon the system and application, the part may have to be flipped over in order to attain complete coverage, but this is quick and easy for any operator due the lack of fixturing or tooling needed to hold the part. Rotary Head Blast Systems can blast a wide variety of complex parts with minimal system or process adjustments.

Rotary Head System Benefits

- Consistency: Increased Quality with Fewer Rejections

- Operational: No Fixturing or Special Tooling Needed

- Productivity: High media flow rate due to the multiple MH-3 blast guns

- Uniformity: Omni-Directional Blast – Ideal for complex geometries

- Efficiency: Automated blast cycles with minimal system or process adjustments

Specifications

- MH-3 Suction-Blast Guns

- Tungsten or Boron Carbide Nozzles

- Four (4), Six (6), or Nine (9) Gun Setup

- Standard Nozzle Size: 3/8” diameter WideSpray with 3/16” diameter inlet

(¼ to 7/16 dia. are available) - Rotating Assembly with Media Flow Regulators

- Universally Adjustable Arms

- Rotary Head Speed: Adjustable 0 to 60 rpm

- Rotary Head Drive: ½ HP, D.C. Motor

- Manual Ball Valve: Individual Gun Control

Multiple guns require less energy and increase productivity by as much as 100%, leading to lower reject numbers compared to manual blasting. The Empire Rotary Blast Head delivers a mixture of the highest blast velocity and media volumes which in return delivers you the most consistently blasted part in the industry and the best return on your investment.

Industry Applications

In the past Rotary Head Systems were seldom used as front-line production tools but now these systems are essential for achieving consistent results. Rotary Heads increase production efficiency and ensure precise blasting of complex work-pieces. Consistent quality and decreased rejections make Rotary Heads ideal for high production facilities. Depending on the specification, dual Rotary Heads in larger volume machines can contribute to improved blast coverage over irregular shapes, especially large casting molds.

- Glass Products: Bottle Molds

- Automotive: Transmission Components

- Aerospace: Turbine Blades & Gears

- Energy: Segmented Turbine Blades

With precise speed and blast control, our Rotary Heads provide a excellent results for a wide variety of applications including surface preparation for advanced coating, non-destructive cleaning, controlled stripping, coating removal, and descaling. Continuous Processing, In-line Conveyer, and Batch Processing Systems are capable of blasting with all different types of media. The Rotary Head Assembly is designed for blasting over a heavy-duty powered turntable or conveyer belt, both clad with durable Ultrawear for years of maintenance-free service.

Key Production Benefits & System Applications

No matter the application, Rotary Heads contribute consistency across production lines and each system is purpose-built to suit the customer’s needs. Every component in Empire’s Rotary Head Systems are of industrial build-quality, designed for durability and maximum up-time. Automated systems reduce occupational stresses by removing the cumbersome task of work-piece manipulation and manual blasting. The versatility of Rotary Heads combined with automation allows facilities to lower their operational footprint by as much as 50%. These benefits lower manufacturing costs and save energy by reducing manual blasting cabinets in favor of automated systems. More customization means increased specificity in design and applications across all industries. From automotive to energy, Rotary Heads withstand the high demands of manufacturing and quality control standards by delivering lower – if not zero rejections.

RS-6060: Batch Processing Continuous Turntable with Rotary Head System

With the RS-6060, only minimal manipulation is required compared to manual blasting and flipping heavy parts during blast cycles. An operator simply has to place a work-piece on a turntable, close the blast door, press a button, and then return after the blast cycle is completed to repeat the process. With the addition of a Batch Processing System, a facility can improve productivity and reduce energy expenditure. These systems are ergonomically designed to reduce the physical stress and repetitive movements associated with manual blasting. This purpose-built machine frees the operator to perform other essential tasks crucial to the production process.

IL4884-RS: In-Line Belt Conveyor System with Suction-Blast Rotary Head

In-line Belt Conveyer Systems also reduce manual operation, which allows for precise work-flow down the production line. For small or flat work-pieces, an In-line Belt Conveyer System delivers finished products through a flat belt, split belt, or roller type conveyer system. A continuous part blow-off manifold with seven Flat Spray Nozzles ensures removal of debris and spent media just before exiting the cabinet

CTT53-RS: Continuous Turntable System with Suction-Blast Rotary Head

Continuous Turntable Systems feature a rotating turntable with an open access area that is shielded from the blast chamber by rubber curtains. The turntable rotates work-pieces through a non-stop blast cycle. An operator retrieves products, flips for additional blasting if necessary, or places another part on the turntable without having to stop or restart the blast cycle. When blasting flat work-pieces, Rotary Heads provide consistent media velocity and coverage over irregular shapes. The MH-3 Suction-Blast Guns can be oriented to access different surfaces, such as blasting the interior and exterior of work-pieces at the same time.

When equipped with Rotary Heads, these systems are highly efficient and achieve tremendous results in a controlled environment. Automation promotes clean working areas by reducing manual blasting equipment and increasing available floor space to accommodate more complex machinery crucial to production. All three systems benefit from the versatility, consistency, and uniformity that only the Rotary Head Blast System provides.

To learn more about our Rotary Head Blast System or any Empire air-blast products, please contact your local Empire distributor or Empire at 215-752-8800 or email [email protected].